Yerson is a brand owned by Beijing Yexiang Technology Co., Ltd. The company was founded in 2016 and headquartered in Beijing, China. We are deeply engaged in the field of radio frequency microwave millimeter wave technology. Our products cover active modules, passive modules, system-level equipment, and can provide high-power switches, power dividers, couplers, attenuators, circulators, filters, phase shifters, power amplifiers, etc. We are also able to independently develop and build switch matrices, phase shifter matrices, attenuation matrices, phase shift matrices, etc. to meet the needs of customers in communication testing, aerospace and aviation, satellite communications, civilian communications and other fields. The company has an independent research and development department with more than 50% of the company’s R&D personnel. The core team members have more than 10 years of experience in radio frequency microwave and electronic measurement research and development. We can customize research and development and production according to customer needs, providing customers with quality products and first-class technical services.

Company introduction

Factory introduction

The factory is located in Dianshanhu Town, Kunshan City, China, with 1500 square meters of standardized production workshop, products are widely used in aviation, aerospace, national defense, shipbuilding, wireless communication, instrument testing and measurement and other fields. Adhering to the tenet of customer first and quality first, Yerson develops and produces high-performance products for various application fields.

-

We have an experienced technical team and manufacturing team, most of whom have nearly 10 years of relevant experience, with R&D personnel accounting for more than 50%.

-

We have a strict product development process, which ensures that the performance indicators and manufacturing quality of products meet industry standards through the layer-by-layer review of schemes, designs, processes, and drawings.

-

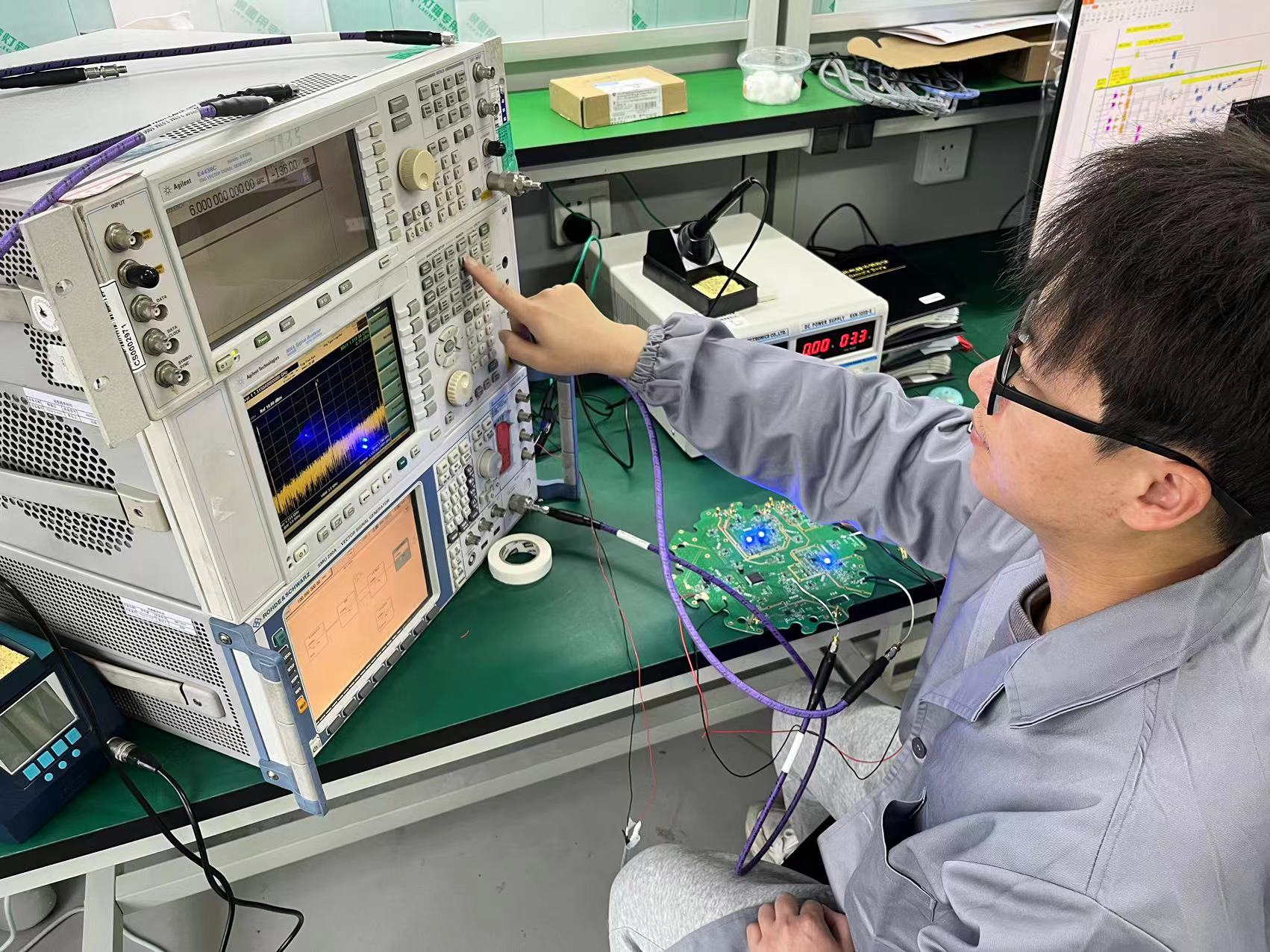

We have industry-leading manufacturing equipment and inspection equipment, strictly control test indicators, and ensure manufacturing accuracy.

-

We have advanced automated manufacturing processes, including automatic patching, automatic bonding, automatic testing, etc., which greatly improve production efficiency and manufacturing accuracy, enabling standardized mass production.

-

Using automatic testing platforms and data analysis techniques, automated and mass production testing is achieved, ensuring product reliability and timely delivery.